Geometric Nonlinear Truss using Updated Lagrangian (UL) – MATLAB Implementation

- Adisorn O.

- May 12, 2025

- 4 min read

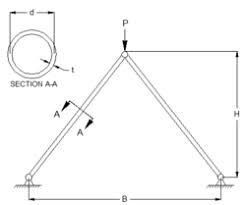

Inclined 2-Bar Truss with Geometric Nonlinearity and Transformation Matrix

This example models a 2-bar inclined truss using the Updated Lagrangian (UL) method. Each bar is inclined, and local stiffness is transformed to global coordinates using a transformation matrix. Geometric stiffness is included in the global stiffness matrix, but element forces are derived only from material strain.

MATLAB Code: Inclined 2-Bar Truss with Transformation

% Properties and Geometry

A = 0.01; E = 200e9; Et = 2e9; sigma_y = 250e6;

coords0 = [0 0; 2 1; 4 0]; % Node 1, 2, 3 (X,Y)

conn = [1 2; 2 3]; % Two truss bars

F_ext = zeros(6,1); F_ext(5) = 0; F_ext(6) = -300e3; % Load at Node 3 (vertical)

% Initialization

u = zeros(6,1); % DOF vector (2 per node)

u_hist = [];

for step = 1:1 % Single load step for simplicity

f_ext = F_ext;

u_iter = u;

for iter = 1:20

K_global = zeros(6); f_int = zeros(6,1);

coords = coords0 + reshape(u_iter,2,[])'; % Update node positions

for e = 1:size(conn,1)

i = conn(e,1); j = conn(e,2);

xi = coords(i,:); xj = coords(j,:);

x0i = coords0(i,:); x0j = coords0(j,:);

L0 = norm(x0j - x0i);

Le = norm(xj - xi);

eps = (Le - L0)/L0;

% Determine current stiffness

Ee = (abs(eps*E) < sigma_y) * E + (abs(eps*E) >= sigma_y) * Et;

N = A * Ee * eps;

% Local to global transformation

lx = (xj(1) - xi(1)) / Le;

ly = (xj(2) - xi(2)) / Le;

T = [lx ly 0 0; 0 0 lx ly]; % Transform 2D axial to global

% Local element stiffness matrices

ke = A * Ee / L0 * [1 -1; -1 1]; % Material stiffness

kg = N / Le * [1 -1; -1 1]; % Geometric stiffness

k_local = ke + kg;

% Global transformation

K_global_e = T' * k_local * T;

% Assemble into global matrix

idx = [2*i-1 2*i 2*j-1 2*j];

K_global(idx,idx) = K_global(idx,idx) + K_global_e;

% Internal force (only from axial strain, not geometric stiffness)

f_local = N * [-1; 1];

f_global = T' * f_local;

f_int(idx) = f_int(idx) + f_global;

end

r = f_ext - f_int;

if norm(r) < 1e-3, break; end

du = K_global \ r;

u_iter = u_iter + du;

end

u = u_iter;

u_hist = [u_hist, u];

end🔧 STRUCTURE OVERVIEW:

3 Nodes, 2D: Node 1 (fixed), Node 2 (middle), Node 3 (right)

2 inclined truss bars: Bar 1 (Node 1–2), Bar 2 (Node 2–3)

6 DOFs (2 per node)

Load applied at Node 3 in the Y-direction

🧠 STEP-BY-STEP EXPLANATION:

✅ 1.

Define Material, Geometry, and Connectivity

A = 0.01; % Cross-sectional area (m²)

E = 200e9; % Elastic modulus (Pa)

Et = 2e9; % Tangent modulus after yield (Pa)

sigma_y = 250e6; % Yield stress (Pa)

coords0 = [0 0; 2 1; 4 0]; % Undeformed (initial) coordinates (3 nodes, X-Y)

conn = [1 2; 2 3]; % Element connectivityEach element connects two nodes.

The truss is inclined — so transformation is required.

✅ 2.

External Load Vector

F_ext = zeros(6,1);

F_ext(6) = -300e3; % Apply vertical load at Node 3 (DOF 6)Node 3 vertical DOF only.

✅ 3.

Initialization

u = zeros(6,1); % Nodal displacement vector (6 DOFs)

u_hist = []; % Store displacement historyInitially no displacements.

✅ 4.

Outer Load Step Loop (1 step shown for simplicity)

for step = 1:1

f_ext = F_ext;

u_iter = u;✅ 5.

Newton-Raphson Iteration Loop

for iter = 1:20

K_global = zeros(6);

f_int = zeros(6,1);Initialize residual and global stiffness for this iteration.

✅ 6.

Update Geometry with Current Displacement

coords = coords0 + reshape(u_iter, 2, [])';Updated Lagrangian: new geometry at each iteration.

✅ 7.

Loop Through Each Truss Element

for e = 1:2✅ 8.

Element Geometry and Strain

xi = coords(i,:); xj = coords(j,:);

x0i = coords0(i,:); x0j = coords0(j,:);

L0 = norm(x0j - x0i); % Original length

Le = norm(xj - xi); % Current length

eps = (Le - L0)/L0; % Engineering axial strain✅ 9.

Determine Effective Modulus

Ee = (abs(eps*E) < sigma_y) * E + (abs(eps*E) >= sigma_y) * Et;

N = A * Ee * eps; % Axial forceBilinear stress-strain model: switch from E to Et at yield.

✅ 10.

Transformation Matrix

lx = (xj(1) - xi(1)) / Le;

ly = (xj(2) - xi(2)) / Le;

T = [lx ly 0 0; 0 0 lx ly]; % Local → GlobalConverts 1D local stiffness and force to 2D global system.

✅ 11.

Local and Geometric Stiffness

ke = A * Ee / L0 * [1 -1; -1 1]; % Material stiffness

kg = N / Le * [1 -1; -1 1]; % Geometric stiffness✅ 12.

Transform to Global Coordinates

K_global_e = T' * (ke + kg) * T;✅ 13.

Assemble into Global Stiffness Matrix

idx = [2*i-1 2*i 2*j-1 2*j];

K_global(idx,idx) = K_global(idx,idx) + K_global_e;✅ 14.

Compute Internal Force from Strain

f_local = N * [-1; 1]; % Axial force vector in local

f_global = T' * f_local; % Convert to global

f_int(idx) = f_int(idx) + f_global;💡 No geometric stiffness used in force — only strain-based!

✅ 15.

Solve Residual and Update Displacement

r = f_ext - f_int;

if norm(r) < 1e-3, break; end

du = K_global \ r;

u_iter = u_iter + du;✅ 16.

Save Final Displacement

u = u_iter;

u_hist = [u_hist, u];✅ Summary

Feature | Implementation |

Geometry update | Yes (UL formulation) |

Geometric stiffness | Yes (added to K matrix) |

Material nonlinearity | Bilinear model (E, Et, σ_y) |

Internal force | Based on strain only (not from k_g) |

Transformation matrix | Converts local stiffness to global coordinates |

Solver | Newton-Raphson with convergence check |